The Wadden & De Duinen on the Baskeweg in Den Helder is ready for the future. The renovation project is the largest application of 3D printed concrete in the Netherlands. A lot has been said and written about the striking undulating balcony screens. But just as interesting is the story behind these concrete-printed screens. How do you anchor the relatively heavy and doubly curved screens and at the same time enlarge the outdoor areas? That was also quite a challenge.

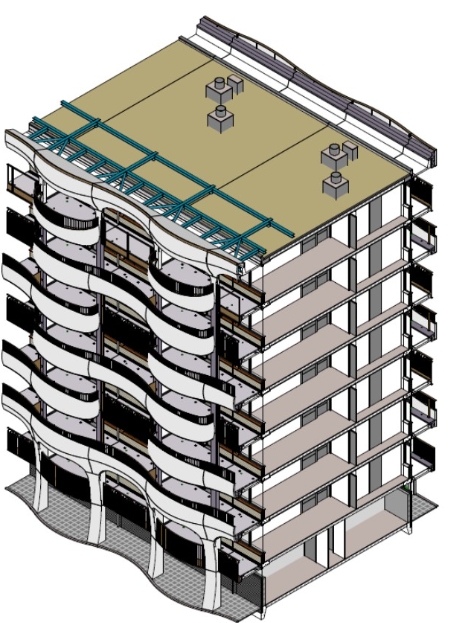

The metamorphosis of the two dated gallery flats from the 1970s is very remarkable, both in terms of construction and aesthetics. Thanks to the facade renovation, the 154 homes are completely ready for the next phase of life. Residents enjoy high-quality insulated facades, larger balconies and the unique new aesthetics. Because a beautiful building that is cherished, not least by its residents, is by definition a sustainable building, is the firm conviction of Kokon architects.

Innovative and affordable design language

The balconies are linked to each other and staggered per floor. In this way they create a dynamic facade image. The balcony screens are connected to the gallery facade via the end wall. The cornice follows the undulating design language of the plinth and screens and ends the building. In total, no fewer than 125 unique screens have been designed. Producing so many different elements would normally not be economically feasible, but with 3D concrete printing, virtually any shape can be made at the cost of series production.

Super slim balcony slabs

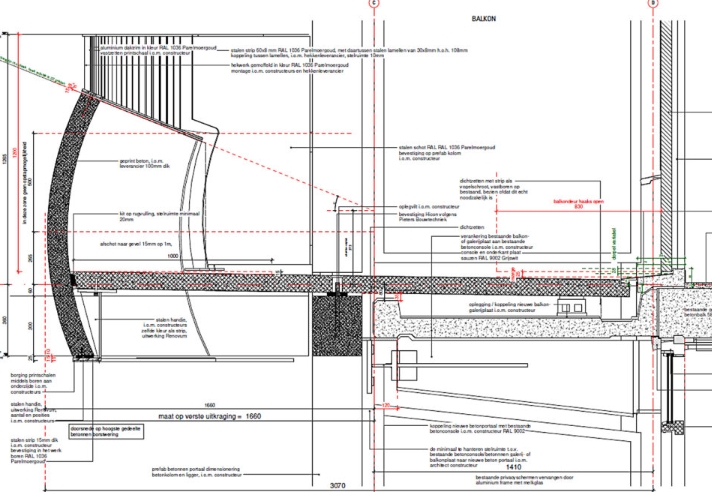

Where the printed concrete screens are the most eye-catching, the construction behind them, although only visible to a limited extent, can certainly be called inventive. The old balconies have been preserved. New, larger balconies in extremely strong but super-slim ultra-high-strength concrete (UHSB) have been placed over this. Thanks to the limited weight and the very small thickness of 60-85 mm, it was possible to place the new balconies over the existing ones. This also improved accessibility. In the new situation, the balconies and floors in the apartments are almost on the same level.

Supporting construction of the screens

The UHSB balcony plates ensure the load transfer from the heavy balcony screens to the construction behind. The screens are anchored to the balcony slabs by means of steel hands. The complex shapes, the amount of fasteners and the positions of the anchors in the prefabricated UHSB balcony slabs required intensive coordination between the architect, contractor, constructor, installer and the manufacturers. The balcony slabs are placed on the existing balconies at the facade and on a new column and portal construction in traditional concrete at the front. The concrete frames are attached to the consoles of the existing building with steel connectors. With these connectors, the wind loads acting on the new facade are transferred to the existing building. At the same time, in these couplings, the dimensional deviations in three dimensions are accommodated.

Wavy balustrades

Not only the concrete screens have a double-curved shape, the gold-coloured balcony railings also wave. There is no straight line. Decorative frames and curls enhance this special effect. Ultimately, all parts – in front of and behind the scenes – connect seamlessly, so that the iconic 3D-printed concrete of De Wadden & De Duinen can shine beautifully in the spotlight.